Splashing Dreamer Mechanical Moving Puzzle DIY Kit METAL-TIME

$ 99,00 $ 49,50

The flights across the Atlantic were a feat for pilots and passengers, although they occurred quite often and regularly in the first half of the 20th century. The journey often lasted most of the day, the machinery was not credible, and the weather conditions created stress every minute. And suddenly a plane appeared, capable of providing unprecedented comfort and safety to passengers. Even in the case of an unforeseen landing over the ocean, it guaranteed the survival of everyone on board. The secret is that it was a Boeing 314 Yankee Clipper floatplane.

It was like one of the floors of a luxury hotel. Pull-out chairs, a restaurant porcelain tableware, and silverware, top-notch service. It was such a plane where James Bond could order his favorite cocktail without getting up and drink it from a crystal glass. The design of the hydroplane and the reserves of resources allowed it to stay in the air for up to a day without refueling and, in case of malfunctions, land on the water and continue its way as a huge boat.

World War II changed the functionality of these aircraft and the luxury of air travel became a thing of the past. Paying tribute to this creation of American engineers, the Metal Time team created the Splashing Dreamer self-assembly kit based on the design of this glorious hydroplane.

PROTOTYPE HISTORY

HISTORY OF THE MODEL FORMATION

Each aircraft model has its own legend. Why did the designers choose this particular design in order to create it into stainless steel, provide moving parts, a spring, and give accents to the color components? Splashing Dreamer is the story of the famous seaplane. This, in addition to its luxury, was an outstanding engineering solution of its time, and many of its technical features are used in modern aircraft.

The Splashing Dreamer is a four-engine monowing hydroplane with distinctive tail fin geometry.

To emphasize the status of this aircraft, the Metal Time team used colored stainless steel parts in the design of the model. The linings on the engine cases, floats-sponsons, and tail stabilizers are made in copper-gold color. The cabin door of the aircraft is also marked with this color.

Features, benefits

The body of the hydroplane is located on a stable stand, which also contains a winding mechanism with a spring and a key. With the help of gears, the movement from it is transmitted to the screws of the engines.

However, the model can be easily separated from the stand, for example, for playing or using as a part of a mock-up or installation. Being disconnected from the central mechanism, the screws can be only moved by turning them by hand.

CHARACTERISTICS, BENEFITS

FEATURES, BENEFITS

You can arrange “air battles” with models, holding them in your hands. You can assemble an airfield layout. You can even simulate the “landing” of a hydroplane on the water, however, you need to understand that the “Splashing Dreamer” will not stay on the surface of the water, since the model has many technological and decorative holes. Nonetheless, the immersion in water does not threaten the model and its mechanisms, because they are made of stainless steel.

The body of the hydroplane is decorated with ornaments imitating waves and flows of water and air carved from metal. In addition to the aesthetic function, this facilitates the model.

Like all Metal Time prefabricated construction kits, the Splashing Dreamer model is made of eco-friendly stainless steel, used in the food industry, and approved for the production of consumer goods and toys.

Assembling the Splashing Dreamer is not an easy task. Mainly because of the complex system of gears which transmit the movement of the spring to the screws of the engines. To achieve the correct operation of the mechanisms, you will need to apply a lot of ingenuity. The assembly process of the model can be a great activity for family leisure.

As a result, your desk or another interior element will be decorated with a model with a special history and character.

For Metal Time, the Splashing Dreamer model is a continuation and development of the “aviation” direction, where several outstanding self-assembly kits have already been made. Its the first time, that a model of an aircraft was created using non-ferrous metal.

Precise cutting of the model eliminates the possibility of cuts during the assembly process.

Pleasant tactile sensations favorably distinguish steel parts from wooden or plastic used in other constructors. Convenient flat packaging made of eco-friendly recyclable cardboard combines the compactness and aesthetics of a status gift.

Prompt shipping and expert packing

We are able offer many shipping options thanks to our long-term relationship with UPS FedEx DHL. Our warehouse personnel are well trained and will pack your goods in accordance with our exact and precise specifications. Before shipping, all goods will be thoroughly examined and safely secured. Each day, we ship to thousands of customers across different countries. Our commitment to become the largest online retailer around the globe is evident by this. The distribution centers and warehouses distribution are in Europe and the USA.

Orders that contain more than one item are assigned processing periods for each item.

Prior to shipment We will conduct a thorough inspection of the items you have ordered. The majority of orders will be shipped within 48 hours. It is expected that delivery will take between 3 and seven days.

Returns

Due to multiple parties such as the factory and the warehouse, we cannot fully manage stock. Stock levels can fluctuate at any time. It is possible that stocks could be depleted after your order has been placed.

Our policy is valid for 30 days. If 30 days have passed without a trace since the purchase, unfortunately we can't offer you a refund or exchange.

In order to be eligible for a return, your product must be unopened and in the same state as you received it. The item must be in its original packaging.

Related products

Wine & Bar_Accessories & Tools

Technology_Charging & Batteries

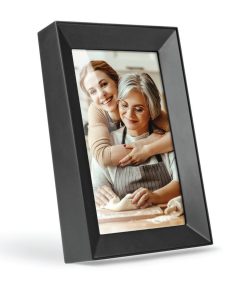

Technology_Digital Frames

17″ WiFi Touchscreen Digital Photo Frame w/ 32GB Memory, Motion Sensor, Auto Rotation Aluratek

Technology_Digital Frames

9″ Digital Photo Frame with Motion Sensor & 16GB Memory Aluratek

Fitness_Type_Connected Fitness

Personal Care & Wellness_Skin Care

Adagio Tourmaline-Infused 25mm Triple Barrel Curling Waver Bibas

Entertainment_Toys

Personal Care & Wellness_Skin Care

Technology_Charging & Batteries

30W USB-C PD Adapter Compatible With Unravel, MacBook Pro – Ultra Compact Ampere LLC

Wine & Bar_Glassware

Home_Accent/Decor

Technology_Digital Frames

8″ WiFi Digital Photo Frame with Touchscreen & 16GB Memory Aluratek

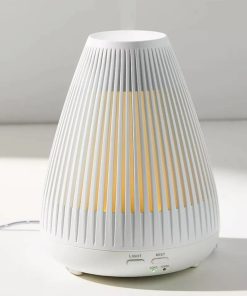

Personal Care & Wellness_Stress Relief

Fitness_Type_Sports Recovery

Home_Furniture

Technology_Digital Frames

Entertainment_Toys

Air Force 3D Electric Mechanical Moving Puzzle DIY Kit METAL-TIME

Personal Care & Wellness_Skin Care

Personal Care & Wellness_Skin Care

Technology_Digital Frames

13.5″ WiFi 3K Digital Photo Frame with Touchscreen LCD and 32GB Memory Aluratek

Home_Furniture

Personal Care & Wellness_Skin Care

Personal Care & Wellness_Skin Care

Pillows/Mattress_Pillows

Wine & Bar_Glassware

Outdoor_Pool/Beach

AirCandy Classic Arm Chair – Metallic Gold Brooke and Dylan LLC

Entertainment_Outdoor Fun

Personal Care & Wellness_Skin Care

Technology_Digital Frames

19″ WiFi Touchscreen Digital Photo Frame w/ 32GB Memory and Motion Sensor Aluratek

Home_Lighting